- HOME

- PRODUCTS

- Face mask machine

- Flat Bed Die cutter

- Strapping Machine

- Folder Gluer Machine

- Flute Laminator Machine

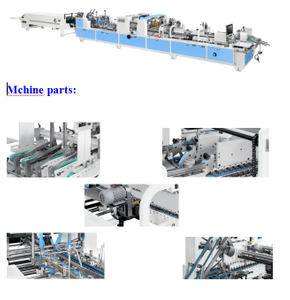

- Double pieces folder gluer

- Window Patching Machine

- Roll Ppaper Cutting Machine

- Carton Box Stitching Machine

- Die cutting&creasing machine

- Duplex Cardboard Production Line

- Thin Blade Slitting Creasing Machine

- Printing Slotting Die cutting Machine

- Pre-feeder/Cardboard Feeding Machine

- Plastic Film BOPP/PET Laminating Machine

- 3/5/7 ply Corrugated Cardboard Production Line

- Printing Gluing Bundling inline(box making machine)

- HD Printing Die cutting Machine with Varnishing&Drying

- ABOUT US

- FACTORY

- NEWS

- CONTACT US